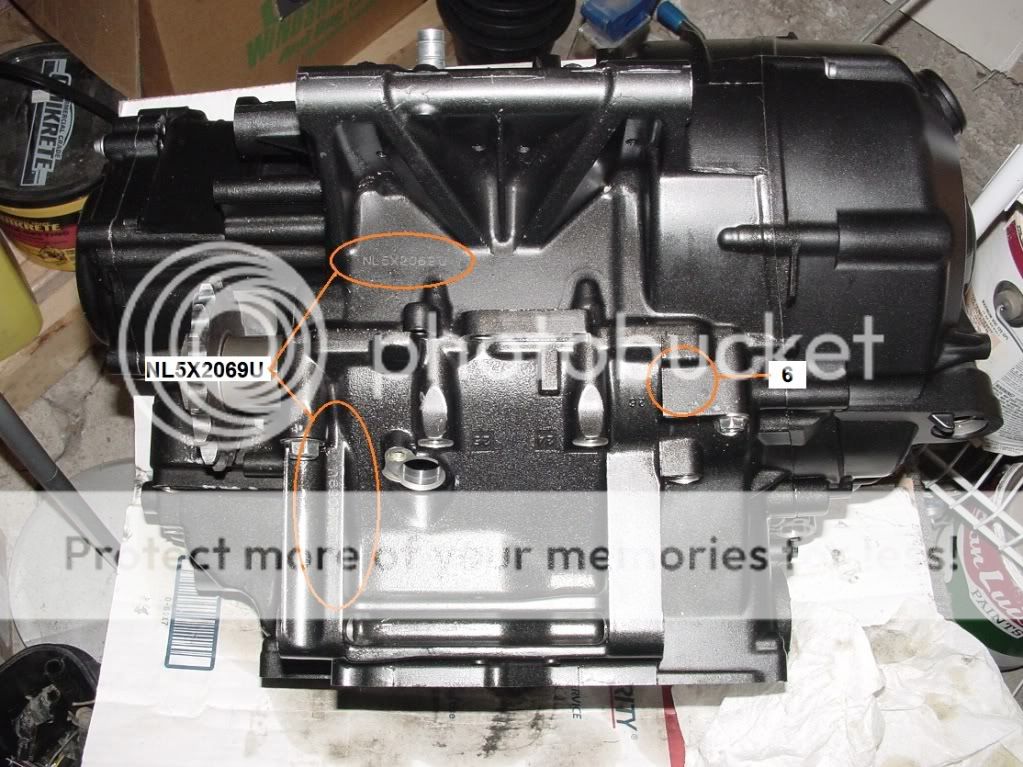

In the service manual, it says to use the numbers stamped on the side of the crank and those on the side of the case to determine the crank and rod bearing color. However, my block has no numbers stamped on the case at all, and all of the numbers on the crank are 2's. Does this mean I need to use all size "2" bearings, which I think are "black" but I will have to check.

Thanks!

Thanks!